Overview of Polypropylene Hollow Board Material

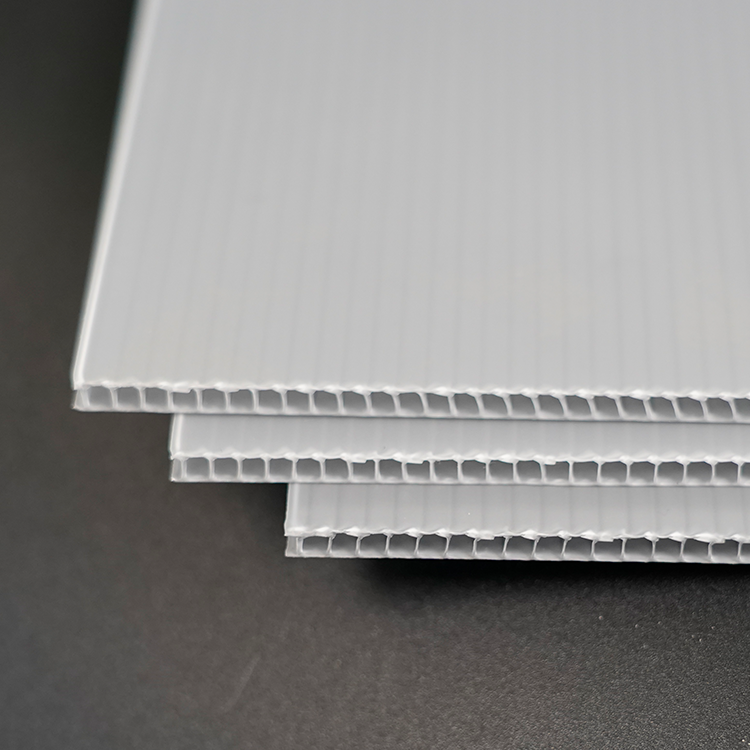

Definition and Characteristics of Polypropylene Hollow Boards

Polypropylene Hollow Board is a lightweight, durable, and environmentally friendly packaging material. Its hollow structure provides exceptional thermal insulation and shock resistance, making it ideal for seafood preservation.

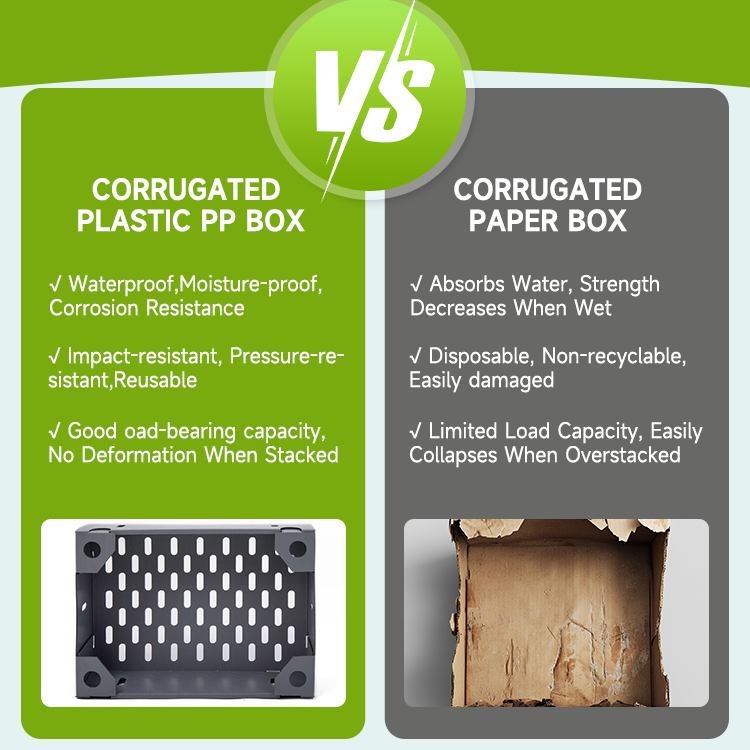

Advantages Over Traditional Packaging Materials

Compared to materials like cardboard and foam, Polypropylene Hollow Board offers:

- Lower thermal conductivity for stable temperatures.

- Resistance to humidity and physical damage.

- Full recyclability, aligning with global sustainability trends.

Addressing Seafood Packaging Challenges

The Need for Effective Seafood Packaging

Seafood preservation demands packaging that maintains low temperatures and withstands humidity and physical impact. Polypropylene Hollow Board meets these challenges by providing a stable environment for perishable goods.

Limitations of Traditional Packaging

Materials like foam and plastic fail to match the durability and eco-friendly properties of Polypropylene Hollow Board, often leading to spoilage and increased waste.

Why Polypropylene Hollow Board Is the Ideal Solution

Superior Thermal Insulation

The hollow design of Polypropylene Hollow Board minimizes heat transfer, maintaining stable temperatures and ensuring seafood freshness during transportation.

Moisture and Shock Resistance

- Absorption rates below 0.01% prevent moisture-related spoilage.

- The hollow structure reduces physical damage during transit, lowering product loss rates.

Sustainability and Cost Efficiency

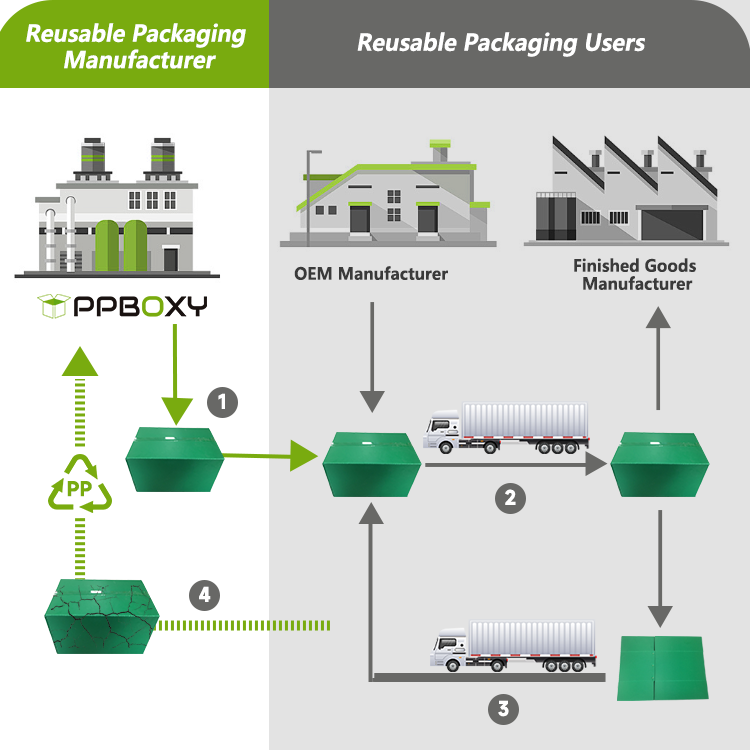

Environmentally Friendly and Recyclable

As a recyclable material, Polypropylene Hollow Board reduces environmental waste and supports circular economy principles.

Long-Term Cost Savings

While initially more expensive than traditional materials, Polypropylene Hollow Board minimizes spoilage and transportation losses, delivering significant cost savings over time.

Consumer and Market Trends

Market Growth in Seafood Packaging

Global demand for Polypropylene Hollow Board is projected to grow at 4.5% annually, driven by its effectiveness in preserving seafood and meeting consumer demands for sustainability.

Rising Consumer Preferences for Sustainability

Over 70% of consumers prioritize eco-friendly packaging. Polypropylene Hollow Board aligns with these preferences by combining superior preservation performance with recyclability.

The Future of Polypropylene Hollow Board

Technological Advancements

Emerging technologies, such as nanotechnology and 3D printing, are enhancing the functionality of Polypropylene Hollow Board, making it more versatile for seafood and other perishable goods.

Expanding Applications

As industries adopt greener practices, Polypropylene Hollow Board is poised to become a cornerstone of sustainable packaging solutions.

Conclusion

Polypropylene Hollow Board is transforming seafood packaging with unmatched insulation, sustainability, and durability. Its innovative design meets the needs of modern businesses and consumers, ensuring quality and environmental responsibility in every shipment.