1. The Environmental Benefits of Using PP Plastic Hollow Sheets

PP plastic hollow sheets offer several significant environmental benefits, making them a preferred choice for businesses looking to reduce their ecological footprint. These benefits include:

1.1 Recyclability

One of the most substantial environmental advantages of PP plastic hollow sheets is their recyclability. Made from polypropylene, these sheets can be recycled at the end of their life cycle, helping to reduce the amount of waste sent to landfills. This recyclable nature supports a circular economy, where materials are reused rather than discarded.

1.2 Reduction in Resource Use

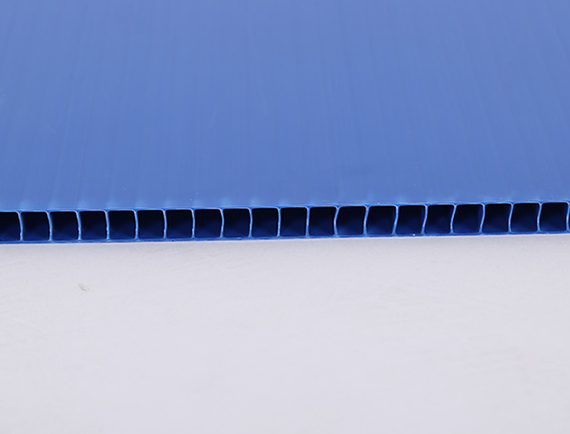

The production of PP plastic hollow sheets requires fewer raw materials compared to other materials with similar applications. Their hollow structure means less plastic is used without compromising strength and durability. This reduction in resource use translates to a lower environmental impact during the manufacturing process.

1.3 Energy Efficiency in Transportation

Due to their lightweight design, PP plastic hollow sheets contribute to lower transportation emissions. Less fuel is required to transport these sheets compared to heavier materials, which reduces the carbon footprint associated with shipping and logistics. This is particularly beneficial for industries that require large quantities of materials to be transported over long distances.

1.4 Reusability

PP plastic hollow sheets are highly durable, allowing them to be reused multiple times in various applications. Whether used in packaging, construction, or advertising, these sheets can withstand wear and tear, reducing the need for single-use products and minimizing waste. Their longevity further enhances their environmental credentials by decreasing the frequency of replacement and disposal.

2. Economic Advantages of PP Plastic Hollow Sheets in Various Industries

2.1 Cost-Effective Durability

PP plastic hollow sheets are known for their exceptional durability, which translates into long-term cost savings. Their resistance to impact, moisture, and chemicals means they last longer than many alternative materials. This durability reduces the frequency of replacements, lowering overall material costs over time. In industries like construction and packaging, where materials are exposed to harsh conditions, the long lifespan of PP plastic hollow sheets is a significant economic advantage.

2.2 Versatility Across Applications

The versatility of PP plastic hollow sheets allows them to be used in a wide range of applications, from protective packaging and signage to construction panels and agricultural containers. This adaptability means businesses can use the same material for multiple purposes, reducing the need to purchase different materials for different applications. This multi-use capability enhances cost efficiency, especially for industries that require diverse material functions.

2.3 Lightweight and Reduced Shipping Costs

One of the economic benefits of PP plastic hollow sheets is their lightweight nature. Compared to other materials, these sheets are much lighter, which can lead to substantial savings in transportation costs. Lower shipping weights reduce fuel consumption and shipping fees, making it more cost-effective to transport large quantities of material. This is particularly beneficial for industries that rely on logistics and distribution, where transportation costs are a significant part of the budget.

2.4 Low Maintenance and Operational Costs

PP plastic hollow sheets require minimal maintenance, contributing to lower operational costs. Their resistance to environmental factors like moisture, UV rays, and chemicals means they maintain their integrity and appearance with little upkeep. In industries where materials are exposed to the elements or heavy usage, this low maintenance requirement helps reduce costs associated with repairs, replacements, and labor.

3. Sustainable Production Practices for PP Plastic Hollow Sheets

3.1 Energy-Efficient Manufacturing Processes

Modern production facilities for PP plastic hollow sheets are increasingly using energy-efficient technologies to minimize their environmental impact. This includes utilizing advanced machinery that consumes less energy during the production process, as well as optimizing manufacturing workflows to reduce energy waste. By lowering energy consumption, manufacturers can significantly reduce their carbon footprint, contributing to a more sustainable production cycle.

3.2 Use of Recycled Materials

Incorporating recycled polypropylene into the production of PP plastic hollow sheets is a key sustainable practice. By reprocessing scrap materials and post-consumer waste, manufacturers can reduce the demand for virgin raw materials, thereby conserving natural resources. This approach not only minimizes waste but also supports the circular economy by keeping materials in use for longer periods.

3.3 Waste Reduction and Recycling Programs

Efficient waste management is a critical component of sustainable production. Many manufacturers implement waste reduction strategies, such as reusing scrap materials in the production process or creating by-products that can be sold or repurposed. Additionally, production facilities often establish comprehensive recycling programs to ensure that any waste generated is properly processed and reintegrated into the manufacturing cycle, rather than being discarded.

3.4 Minimization of Water Usage

Water conservation is another important aspect of sustainable production practices. In the production of PP plastic hollow sheets, manufacturers are adopting technologies that reduce water usage or recycle water within the production process. This not only conserves a vital resource but also reduces the environmental impact associated with water extraction and treatment.

3.5 Eco-Friendly Additives and Treatments

Some manufacturers are now using eco-friendly additives and treatments during the production of PP plastic hollow sheets. These additives can enhance the material’s properties, such as UV resistance or flame retardancy, without introducing harmful chemicals into the environment. This practice ensures that the final product is both high-performing and aligned with environmental standards.

FAQs About PP Plastic Hollow Sheets and Sustainability

PP plastic hollow sheets contribute to environmental protection in several ways. They are made from recyclable materials, reducing the need for virgin resources. Their lightweight nature reduces transportation emissions, and their durability means they can be reused multiple times, minimizing waste. Additionally, sustainable production practices further enhance their environmental benefits.

What makes the production of PP plastic hollow sheets sustainable?

The production of PP plastic hollow sheets is considered sustainable due to practices such as using energy-efficient machinery, incorporating recycled materials, and minimizing waste and water usage. Many manufacturers also use eco-friendly additives and treatments, ensuring the final product has a lower environmental impact while maintaining high performance.

Can PP plastic hollow sheets be used in eco-friendly construction projects?

Absolutely. PP plastic hollow sheets are ideal for eco-friendly construction projects due to their durability, recyclability, and resistance to environmental factors. They can be used in applications such as wall panels, roofing, and temporary structures, offering both functional and environmental benefits.

What is the lifespan of PP plastic hollow sheets, and how does it affect sustainability?

PP plastic hollow sheets have a long lifespan due to their resistance to impact, moisture, and chemicals. This durability means they require less frequent replacement, reducing the demand for new materials and lowering the overall environmental impact. Their extended usability is a key factor in their sustainability profile.