1. What is PP Hollow Sheet?

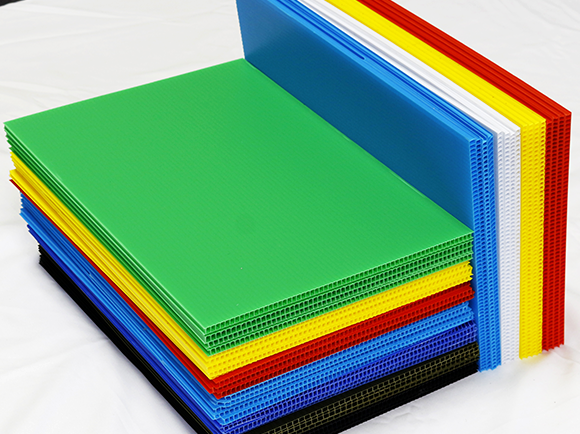

PP hollow sheets, or polypropylene hollow sheets, are lightweight, durable materials made from polypropylene resin. They have a hollow structure that provides strength and flexibility, making them ideal for a range of applications. The material is known for being moisture-resistant, impact-resistant, and easy to customize, which contributes to its growing popularity in various industries.

2. Key Applications of PP Hollow Sheet in Packaging

PP hollow sheets are increasingly becoming a staple in the packaging industry due to their versatile properties and adaptability to various packaging needs. Here are some key applications:

2.1 Custom Packaging Solutions

PP hollow sheets are ideal for creating custom packaging solutions like boxes, dividers, and trays. Their lightweight yet sturdy nature ensures that products are securely packaged without adding unnecessary weight, reducing shipping costs. These sheets can be easily cut and molded into different shapes and sizes to fit specific packaging requirements, making them highly adaptable for different products.

2.2 Protective Layer Pads

In industries where products are stacked or transported in bulk, PP hollow sheets are often used as protective layer pads. These pads act as barriers between layers of products, preventing damage during transportation and storage. Their impact resistance and durability make them an excellent choice for protecting delicate items, such as electronics, glassware, and automotive parts.

2.3 Food Packaging

The chemical resistance and hygiene properties of PP hollow sheets make them suitable for food packaging applications. They are commonly used to create packaging for fresh produce, bakery items, and other perishable goods. The sheets can be easily sanitized, ensuring that food remains uncontaminated, while their moisture resistance keeps the packaging intact even in humid environments.

2.4 Returnable Packaging Systems

PP hollow sheets are frequently used in returnable or reusable packaging systems. These systems are designed for multiple uses, reducing waste and providing a sustainable packaging solution. PP hollow sheets’ durability ensures that the packaging can withstand repeated handling and transportation, making them a cost-effective and environmentally friendly option for businesses looking to reduce their carbon footprint.

3. The Role of PP Hollow Sheet in Construction

PP hollow sheets are increasingly being utilized in the construction industry due to their exceptional properties that make them suitable for various applications. Here’s how they play a significant role in construction:

3.1 Formwork for Concrete Casting

PP hollow sheets are widely used as formwork in concrete casting. Their lightweight nature makes them easy to handle and install, reducing labor costs and time on construction sites. The smooth surface of PP hollow sheets ensures that the concrete forms are even and clean, resulting in a high-quality finish. Additionally, these sheets are reusable and resistant to water and chemicals, making them a durable and cost-effective option for construction projects.

3.2 Temporary Protective Flooring and Wall Covering

During construction, PP hollow sheets are often used as temporary protective flooring and wall coverings to shield surfaces from damage. These sheets provide a robust barrier against impacts, spills, and abrasion, ensuring that the underlying surfaces remain intact throughout the construction process. Their easy installation and removal make them a convenient choice for protecting valuable finishes, especially in high-traffic areas.

3.3 Wall Cladding and Partitions

PP hollow sheets serve as an effective material for wall cladding and partitioning. They offer excellent insulation properties, contributing to the thermal and acoustic efficiency of buildings. These sheets can be easily cut and customized to fit various architectural designs, making them a flexible option for interior and exterior applications. Moreover, their resistance to moisture and corrosion ensures long-lasting performance, even in challenging environments.

3.4 Lightweight Roofing Solutions

In construction projects where weight reduction is crucial, such as temporary structures or portable buildings, PP hollow sheets are used for lightweight roofing. Their strength-to-weight ratio allows them to provide adequate protection against the elements while being easy to transport and install. The UV resistance of PP hollow sheets also makes them suitable for outdoor use, ensuring that the roofing remains durable and effective over time.

4. PP Hollow Sheet in Advertising and Signage

PP hollow sheets have become a popular choice in the advertising and signage industry due to their versatility, durability, and cost-effectiveness. Here’s how they are used:

4.1 Durable Outdoor Signage

PP hollow sheets are ideal for creating outdoor signs due to their durability and weather resistance. These sheets can withstand exposure to rain, sunlight, and temperature fluctuations without degrading or losing their structural integrity. This makes them a reliable choice for long-term outdoor signage, such as billboards, road signs, and promotional banners, ensuring that messages remain visible and effective over time.

4.2 Lightweight and Portable Displays

The lightweight nature of PP hollow sheets makes them perfect for portable displays used in trade shows, exhibitions, and events. They can be easily transported and set up, reducing the effort and costs associated with installation. Despite their light weight, these sheets are sturdy enough to maintain their shape and support various design elements, making them a practical choice for temporary promotional displays and pop-up stands.

4.3 Customizable Advertising Boards

PP hollow sheets offer excellent printability, allowing for vibrant, high-quality graphics to be applied directly to the surface. This makes them a popular choice for creating customized advertising boards, including point-of-purchase displays, retail signs, and promotional boards. Their ability to be cut into various shapes and sizes provides flexibility in design, enabling businesses to create eye-catching and unique advertising solutions tailored to their brand.

4.4 Cost-Effective Marketing Solutions

One of the main advantages of PP hollow sheets in advertising and signage is their cost-effectiveness. Compared to other materials like metal or acrylic, PP hollow sheets are more affordable while still offering durability and aesthetic appeal. This makes them an attractive option for businesses looking to maximize their marketing budget without compromising on quality or impact. Additionally, their recyclability aligns with growing environmental awareness, providing a sustainable solution for advertising needs.

FAQS

1. What are the main advantages of using PP Hollow Sheet?

PP Hollow Sheets offer benefits such as lightweight construction, impact resistance, chemical resistance, and ease of recycling.

2. Can PP Hollow Sheet be used in outdoor applications?

Yes, PP Hollow Sheets are weather-resistant and suitable for various outdoor applications, including signage and protective covers.

3. How does PP Hollow Sheet compare to other materials?

Compared to materials like metal or wood, PP Hollow Sheets are more lightweight, cost-effective, and resistant to moisture and chemicals.

4. Is PP Hollow Sheet easy to recycle?

Yes, PP Hollow Sheet is recyclable and can be processed into new sheets or other products, supporting sustainability efforts.

Conclusion

In summary, PP Hollow Sheet is a highly adaptable material with a wide range of applications across packaging, construction, and environmental sectors. Its unique properties make it an excellent choice for various needs, offering durability and sustainability. By understanding its uses and benefits, you can make informed decisions for your projects and contribute to a greener future.